Products

BENEFITS FROM 25 YEARS OF EXPERIENCE

The continuous development and optimization of our software CCS2000 and our experience and knowledge are the basis for our range of services that fit to your specific production infrastructure.

CCS2000 – FLEXIBLE AND RELIABLE

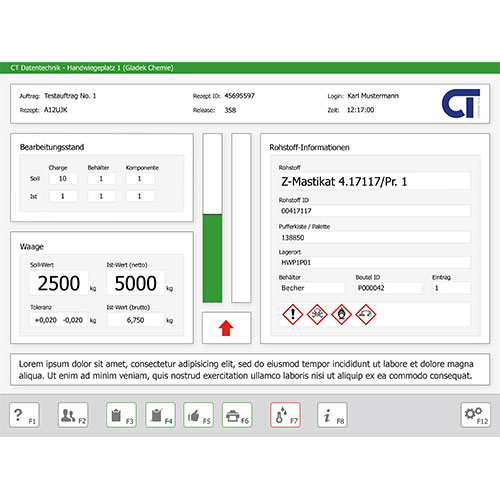

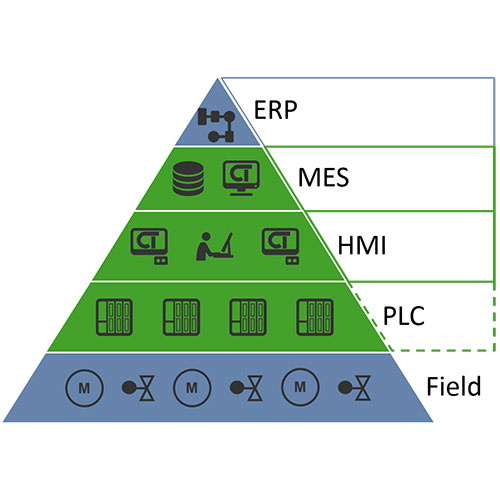

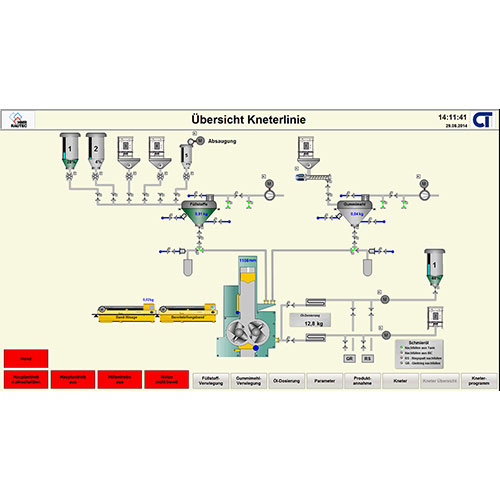

The Compound Control System CCS2000 is a process control system which allows the complete monitoring and controlling of all processes in the mixing room. The software ensures a high quality automation of various production processes and is used by our partners primarily in the areas of rubber and brake pad manufacturing.CCS2000 is constantly enhanced by our team to offer our customers the best solution for the manufacturing and conditioning of mixtures.

The automatic control of the production process offers the following advantages:

- quality assurance, from raw materials to final products

- improvement for quality audits

- increased flexibility in order processing

- smoothing of the production sequences by means of time planning and balancing of available resources

- increased productivity through the implementation of time planning

- rationalization through avoidance of production rejects and losses

- reduction of verification expenses due to controlled process flows

In addition to the quality assured production process the software is also responsible for administrative tasks:

- master data management (material lists, material data, work flows etc.)

- order management (e.g. calculation of material needs)

- storage volume management (material consumption, minimum stock quantity control)

For evaluation, we provide a variety of sophisticated products:

- CCS2000 ART (Analyzing Reporting Tool) for graphical evaluation

- CCS2000 PDA (Production Data Acquisition) for economic considerations and error analysis

- CCS2000 Journal for a continuous monitoring of the CCS2000

- CCS2000 WIS (Web Information Service) for web based analyzing of data

Of course, the CCS2000 must not operate as a standalone system. If demanded, it can be integrated into existing IT worlds or we can develop interfaces to various other systems, so that the customer gets a harmonic and homogeneous system. Examples:

- ERP-interfaces (SAP, Dynamics, Sage, Infor, AS/400-based systems, …)

- laboratory systems (MonTech, Scarabaeus, Eclipse)

- other control systems

CCS2000 in usage

Our customer WAGU made an image movie of their company. In this movie our process control system CCS2000 is also a major part.

At WAGU our CCS2000 is responsible for the complete production process incl. order management, laboratory connection and stock management. All processes are implemented into one system with maximum efficiency.